What Products Come From Farm Waste Products?

Complete Biogas Systems -The biogas digester can turn the waste into the following products that benefit the farming and agriculture industries. A biogas digestor which is one of the top offerings from MTD because of its efficiency in taking organic matter from and under controlled conditions converts it to energy. The biogas digestor is a large and sealed container for the manure or other organic materials from livestock or poultry, green waste from agriculture, sewage, or food waste.

Biogas

Electricity

Liquid Fertilize

Making Biogas From Manure

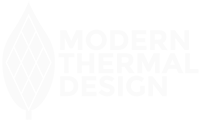

The MDT engineers and Biogas specialists will help you create your own Biogas plant. To begin understanding the process we are making available the the most recent Anaerobic (Ad) Screening Tool. This tool created by the U.S. Environmental Protection Agency on behalf of the Global Methane Initiate (GMI) is for biogas developers to conduct preliminary feasibility assessments of the volume their AD system could generate based on available waste streams.

If you would prefer a fast track to a feasibility study, just let the experts at MTD handle the heavy lifting, Just complete this MTD INTAKE BIO-GAS and contact us.

What are the benefits of biogas digesters?

There are several benefits to using this method to remove waste products. They include the following.

- Your farm smells better and increases real estate prices

- Reduces air, soil, and water pollution that your neighbors complain about

- Financial assistance and incentives to go to digesters

What products can be put in the digester?

There are several products you put in the digester. These include the following.

- Swine, chicken, cow manure

- waste whey from milk products

- Leftover crop residue after the food has been taken from it, such as corn stalks, watermelon rind, etc.

What do you need to set up a biogas plant?

To set up a biogas plant that uses waste products to make biogas you will need the following.

- An integrated container biogas digester

- Pipeline

- Biogas appliances

- Compressors

- Biogas powered generator

The container anaerobic reactor is constructed of double layer of stainless steel plates with 5cm thick foam insulation layer installed between. The anaerobic reactor has a heat pump, a temperature controlling device, and a stirring device.

We can train you to install, or we install.

How a Biogas Plant Works

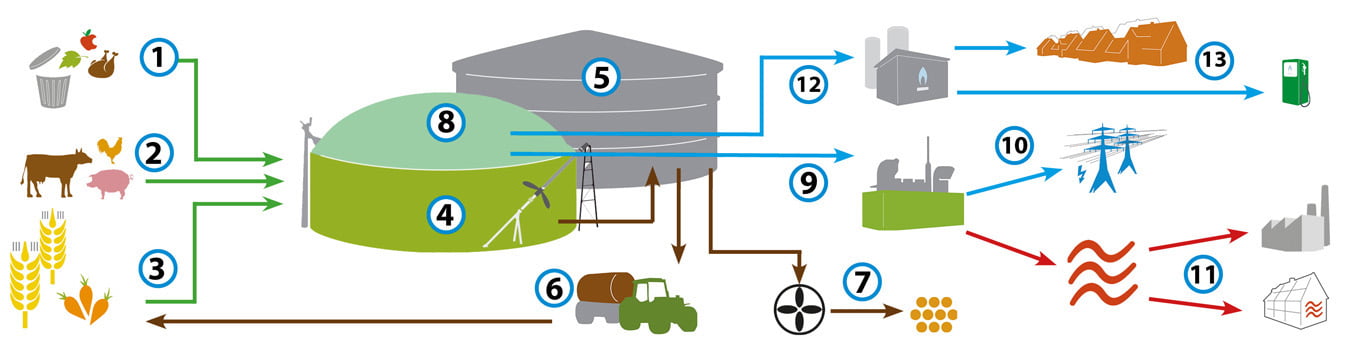

The biogas plant works like this.

- Organic materials such as food remnants, fats, or sludge are put into the plant as a substrate.

- Renewables such as corn, beets, grass, and others serve as microorganisms in the biogas plant.

- Manure is also added.

- The fermenter heated to 38 to 40C will cause the substrate to decompose by microorganisms without light or oxygen.

- The substrate that has decomposed goes to the end storage tank, and it then can be used as liquid fertilizer, but it can also be dried and used dry.

- The biogas that is generated is stored in the roof of the tank; from there it is burned in the combination heat and power plant. It makes heat and electricity.

- The electricity is fed into the power grid.

- The heat made can be used to heat buildings, dry wood, or harvest goods.

- The gas is sent to the national grid or gas stations.

Are biogas plants in all 50 states?

All 50 states have biogas plants for a total of 2.200 plants. Europe has around 10,000 sites. The US has the potential of 14,958 sites that could be biogas plants.

Technology has also made available personal biogas plants for the backyard. These backyard plants can provide two to six hours of cooking gas for your personal use a day. The downside to these is they take up space in the yard and sit above the ground. You may not like the way it looks in the yard.

Are you ready to set up a biogas plant?

If you are interested in setting up a complete biogas system to power your own biogas plant, Modern Thermal Design has everything you need. The integrated canister biogas digester, duct line, biogas machines, compressors, and biogas-powered producers are all ready for you to install or Modern Thermal Design will install.

The container anaerobic reactor is made from a double layer of stainless steel plates that contain 5 cm of foam insulation between the layers. The reactor has a heat pump a temperature controlling device and a stirring device. This will have you up and running in no time.

Conclusion

Biogas plants deliver clean renewable energy that cuts down on soil and water pollution. Smaller communities can do a community biogas plant that the community can sign up for service.

We will see many more biogas plants in the future and hopefully, the technology will move ahead enough to place them in densely populated cities too.